Global Unisol Pvt. Ltd

-

Head Office: Tower B 2nd Floor, Unit No 211, Logix Technova, Sector 132, Noida, Gautam Buddha Nagar, Uttar Pradesh - 201306

Address

-

Branch Office: Branch Office: No. 2111,, 2nd Cross Road, D-Block, Gayatri Nagar, Rajajinagar, Bengaluru - 560010.

Address

-

Call Us: +91 97436 20456

(Mon - Sat)

-

Monday - Saturday

(10am - 06 pm)

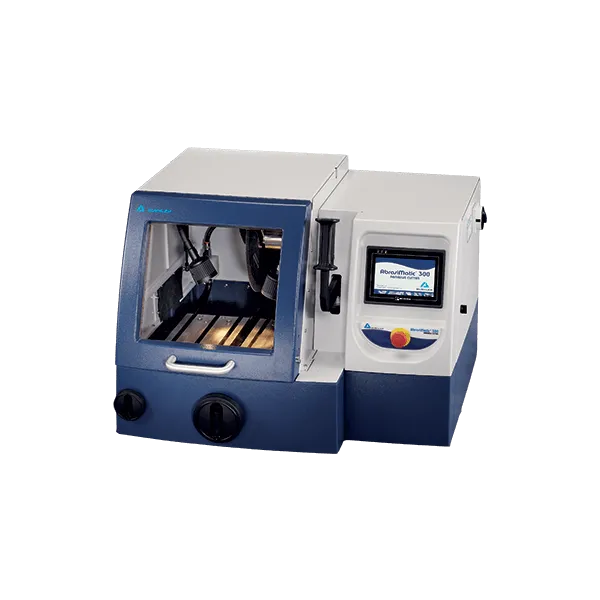

AbrasiMatic 300 Automatic and Manual Abrasive Cutter

AbrasiMatic 300

Automatic and Manual Abrasive Sectioning Machine

Our Brochure

AbrasiMatic 300 Abrasive Cutter by Buehler is a versatile, high-performance cutting solution designed for manual and automatic sectioning of a wide variety of materials. With advanced features like dual cutting modes, XYZ axis movement, and a powerful 5Hp motor, this abrasive cutter is ideal for laboratories, manufacturing, and research facilities that demand precision and efficiency in metallographic sample preparation.

Key Features of AbrasiMatic 300

-

Dual Cutting Modes

Offers both manual and automatic cutting options, providing unmatched flexibility for diverse sample materials and geometries. -

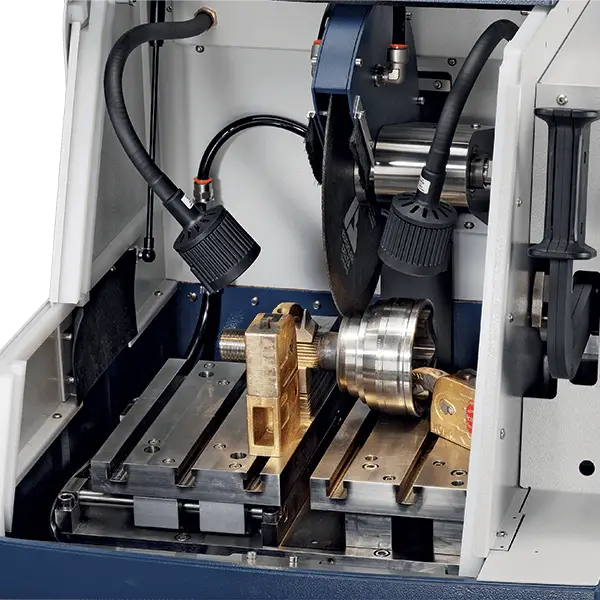

XYZ Axis Movement for Precision Cutting

Standard Y and Z-axis movement ensures precise sectioning, with an optional X-axis for serial cutting, making it ideal for repetitive tasks. -

Large 12-Inch Blade Capacity

Accommodates blades up to 12 inches [305mm] in diameter, enabling sectioning of samples up to 4.375 inches [110mm] in diameter. -

High-Performance Motor

Powered by a robust 5Hp [3.7kW] motor, the AbrasiMatic® 300 delivers superior cutting torque, ensuring efficient processing of hard and challenging materials. -

User-Friendly Touchscreen Interface

Features an intuitive touchscreen control panel for easy setup and operation, allowing users to adjust cutting parameters with precision. -

Enhanced Visibility and Safety

Includes a large viewing window with adjustable LED lighting, a retractable hood, and safety interlocks, ensuring operator safety during cutting operations. -

Quick Cleaning and Maintenance

Equipped with a washdown hose for fast cleanup and a catch basket for easy retrieval of sectioned parts, minimizing downtime.

Enquire Now

Applications of AbrasiMatic 300

- Metallographic Sample Preparation: Ideal for cutting metals, alloys, composites, and other materials for testing and analysis.

- Failure Investigation: Prepares precise sections for detailed examination of material defects or fractures.

- Routine Laboratory Work: A versatile machine for consistent and efficient sample preparation.

- Research and Development: Supports advanced cutting techniques required in R&D projects.

Similar Products

Our Brochure

Specifications

| Feature | Details |

|---|---|

| Voltage Options | 230VAC, 60Hz; 460VAC, 60Hz; 220VAC, 50Hz; 380VAC, 50Hz (3 Phase) |

| Power Consumption | 4.0kW |

| Motor Power | 5Hp [3.7kW] |

| Sound Rating | 78dBA (no load) |

| Recirculation Tank Capacity | 22 gallons [83 liters] |

| Lighting | Two LED Goosenecks |

| Abrasive Wheel Diameter | Maximum 12 inches [305mm]; Arbor size 1.25 inches [32mm] |

| Cutting Chamber Dimensions | 36 W x 22 D x 8 H inches [914 x 558 x 203mm] |

| Auto Y-Axis Feed Rate | 0.7-5 in/min [0.3-2mm/sec] |

| Maximum Cut Diameter | 4.375 inches [110mm] |

| Wheel Speed | 2600rpm @ 50/60Hz; 8200 surface ft/min [2700 surface m/min] |

AbrasiMatic 300 Ordering Information

| Part Number | Voltage | Cutting Axes |

|---|---|---|

| 10-2190-260 | 200-240VAC, 60Hz | Y and Z Axes Cutting |

| 10-2190-460 | 440-480VAC, 60Hz | Y and Z Axes Cutting |

| 10-2190-250 | 200-240VAC, 50Hz | Y and Z Axes Cutting |

| 10-2190-400 | 380-400VAC, 50Hz | Y and Z Axes Cutting |

| 10-2193-260 | 200-240VAC, 60Hz | Additional X Axis Cutting |

| 10-2193-460 | 440-480VAC, 60Hz | Additional X Axis Cutting |

| 10-2193-250 | 200-240VAC, 50Hz | Additional X Axis Cutting |

| 10-2193-400 | 380-400VAC, 50Hz | Additional X Axis Cutting |

We’re Just a Message Away

Connect with Us for Inquiries, Support, or Partnerships

We’re here to assist with your analytical and material testing needs. Whether it’s product information, technical support, or partnership inquiries, contact our team today!

At Global Unisol, we are committed to providing you with top-quality solutions and support. Reach out to us for any queries