Global Unisol Pvt. Ltd

-

Head Office: Tower B 2nd Floor, Unit No 211, Logix Technova, Sector 132, Noida, Gautam Buddha Nagar, Uttar Pradesh - 201306

Address

-

Branch Office: Branch Office: No. 2111,, 2nd Cross Road, D-Block, Gayatri Nagar, Rajajinagar, Bengaluru - 560010.

Address

-

Call Us: +91 97436 20456

(Mon - Sat)

-

Monday - Saturday

(10am - 06 pm)

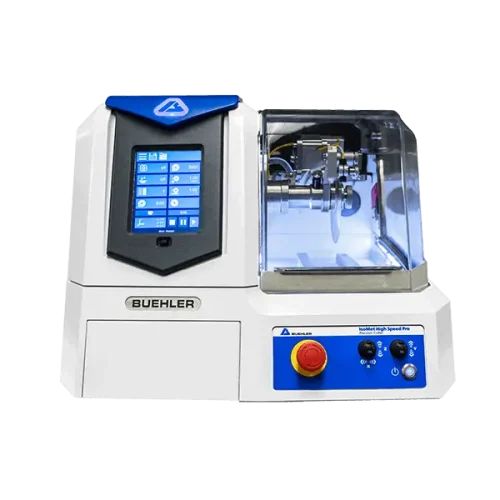

IsoMet High Speed Pro

IsoMet High Speed Pro

Automatic Precision Sectioning Machine

Our Brochure

The IsoMet High Speed Pro is an advanced automatic precision sectioning machine designed for laboratories and industrial environments requiring high-speed, high-precision cutting. With an 8-inch [203mm] tabletop design, a powerful motor, and cutting-edge features, it ensures exceptional surface quality and ease of operation. Paired with Buehler’s diamond or CBN blades and Cool 3 coolant, it provides a comprehensive solution for precision sectioning needs.

Key Features of IsoMet High Speed Pro

-

Unparalleled Precision and Consistency

- Precise feed rate, cut length, and positioning for accurate cuts.

- Automatic blade dressing for clean and consistent cutting quality.

- Stored methods for sample-to-sample consistency and repeatability.

- SmartCut technology to prevent overloading the cutting force on samples.

-

Speed and Efficiency

- Powered by a robust 2.7Hp [2kW] motor for fast and efficient cutting.

- Rapid Rail system enables quick and easy vising setup.

- Abrasive vising table can be swapped in for larger samples, enhancing versatility.

- Streamlined workflow with stored methods for one-button setup of cutting parameters.

-

User-Friendly Controls

- 3-axis joystick control for precise movement and easy setup.

- Intuitive touchscreen interface with advanced programming capabilities.

- High range of movement simplifies positioning for a variety of sample sizes.

Enquire Now

Applications of IsoMet High Speed Pro

- Metallographic Sample Preparation: Precise sectioning for microscopic analysis and material characterization.

- Quality Control Testing: Ensure product integrity and compliance with industry standards.

- Research and Development: Support innovative material analysis and development projects.

- Educational Laboratories: Perfect for teaching precision cutting techniques in academic settings.

Benefits of the IsoMet High Speed Pro

- Precision and Accuracy: Achieve high-quality, repeatable cuts with advanced control features.

- Time-Saving Design: Streamlined setup and cutting processes improve workflow efficiency.

- Versatile Applications: Ideal for cutting soft metals, hard ceramics, composites, and more.

- Robust and Reliable: Built with durable components for long-term use in demanding environments.

Similar Products

Our Brochure

Specifications

| Feature | Description |

|---|---|

| Cutting System Specifications | |

| Operation | Automatic, Manual, or SmartCut control Linear Blade Feed |

| Units | English and Metric |

| Blade Movement Axis | Horizontal and Linear (X, Y, Z) |

| Display | 6.5in LCD Display with LED Backlighting |

| Controls | Touch Screen; Precision Controllers |

| Lighting | 2 LED Strip Adjustable brightness |

| Programming | Retains Last Settings Serial Sectioning |

| Laser | Optional Green Laser |

| Blade Position Settings | Horizontal: 0 – 2in [0 – 50mm] |

| Cut Length Range | .01 – 7.25in [1mm – 184mm] |

| Cut Length Increment | 0.01in [.25mm] |

| Feed Rate Range | .04 – 1in/min [1.2 – 25.4mm/min] |

| Feed Rate Increment | 0.01in increments [1mm increments] |

| Blade Speed | 1000-5000rpm |

| Cut Capacity (Diameter) | 2.8in [71mm] |

| Coolant Systems | Built-in Recirculating System, 1gal [4L] |

| Flow Rate Wash Down Hose | 2L/min |

| Flow Rate on Blade | 2.5L/min |

| Wafering Blade Diameters | 3 – 8in [76 – 203mm] |

| Abrasive Blade Diameters | 5 – 8in [127 – 200mm] |

| Cut Chamber Size | 9in x 20in [228mm x 508mm] |

| Machine Dimensions | Width: 24in [610mm], Depth: 30in [762mm] |

| Height (Hood Opened) | 36in [915mm] |

| Height (Hood Closed) | 19in [483mm] |

| Weight | 157Lbs [71.2kg] |

| Electrical Specifications | |

| Motor Power at 220VAC | 2.68Hp [2kW] |

| Main Power | 100 – 240VAC, 50-60Hz, 1 Phase |

| Noise Level | 58dB |

| Safety Features | Interlock Hood Switch, Emergency Stop |

| Compliance | CE Directives |

We’re Just a Message Away

Connect with Us for Inquiries, Support, or Partnerships

We’re here to assist with your analytical and material testing needs. Whether it’s product information, technical support, or partnership inquiries, contact our team today!

At Global Unisol, we are committed to providing you with top-quality solutions and support. Reach out to us for any queries